Description

NOTE:No service is available for islands and post codes as belows:

Spain:The postcode starts with 07, 35, 38, 51, 52.

Portugal:The postcode starts with 9.

France:The postcode starts with 001、002、20、97-99.

[Ship from EU]QueenAnt PRO Ball Screw CNC Machine Mechanical kit

The QueenAnt(PRO)is a Industrial Grade CNC with Ultra High Precise Ball Screw and Full Track Linear Rail Upgrade based on very well-received WorkBee CNC and QueenBee CNC Machines.It’s 100% Independent research,development,design and owned by YUYONG INDUSTRY. Our R&D department fully listened to community members’ requests for a high-precision CNC machine,Combining our own technology,Multi-party correction and testing and continuous improvement, which lasted 1 year,then the Industrial Grade QueenAnt Ball Screw CNC Machine is born!

Its many super upgrades have greatly improved the mechanical performance of the entire machine in terms of frame design or rigidity and precision.

With Full Series size,no matter Cutting or 3D carve wood,pcb plastics, aluminum, etc. to create beautiful intricate 3D carvings, inlays, furniture, signs, plaques, amazing works of art and so much more. All can be achieved here!

It will become a most popular Ball Screw CNC machines for Factory,Tech,Electric,Art,Furniture,DIYers etc.

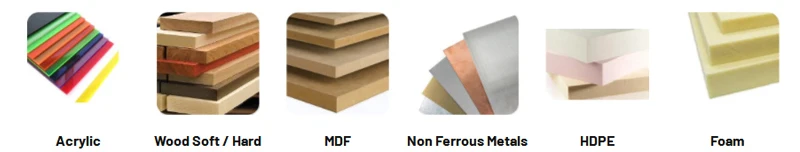

Compatible Material for Cutting/Milling/Engraving:

- Aluminium / Hard Wood / Soft Wood / Oak / Plexi Glass / Delrin / HDPE / Foam

This Mechanical Kit Includes:

- QueenAnt CNC PRO V2 Mechanical Kit

- 1605/1610 Big Diamater Precise Ball Screws

- 4 sets x Close-Loop Motors and Close-Loop Driver 2.45N.m/3.6N.m(Optional)

- All Extrusions are M5 Tapped as where it is necessary

Specs of Close-Loop Stepper Motors and Close-Loop Drivers:

Drive characteristics:

Model:HBS57

Type: DSP Closed loop stepper drive

Maximum peak current: 5A

Impulse response frequency: 200KHz

Micro-stepping driver: 2-256ppr

Voltage: DC16-80V

Protective function: Over voltage, over current, tracking error, over proof

Signal input Compatible:5-24V signal (Don’t need a resistor)

Control Way: 32 bit DSP Vector Closed Loop

Advantage: No step to lose, Low noise, little vibration and high efficiency, low heat

Motor electric parameter:

Shaft Diamater:8mm

Step angle/phase: 1.8 Degree

Hold torque: 2.45N.m/3.6N.M

Encoder: 1000line

Rated voltage/current: 4.2A

Resistance: 0.85ohm

Inductance: 3.6mH

Class of insulation: B

Please note:

- This is mechanical kit, all electronic parts are Not included with this kit.

- We do not provide technical support for software debugging.

- Any Mains power connections must be installed by a Licensed electrician or suitability qualified person

- Do not turn the screw nut out, otherwise the steel ball inside will break away from the raceway and cannot be installed again.

- Please lubricate the guide rail and ball screw regularly to ensure lubrication.

- Machine assembly may require different sizes and types of tools.

YUYONG 4.0 Industrial Age

- Full inspection and test for each small item before shipment to make sure 100% Quality!

- 100% Exchange and Return Service fully free for non-human damages!

- Professional online After-Sales Support!

- Up to 1.5 years long warranty!

The WorkBee is a popular and well-designed CNC machine, it use V Wheel system to assembly X Y Z Axis to roll,If you have ever assembled a machine, you will know how frustrating it is to adjust the wheel to the same force balance.And Also,the wheel system only bear one direction force.When you put heavy spindle on Z Axis or Load on X Axis,the Wheels are not enough to support the weight,uneven force caused flex of X And Z Axis long term.

YUYONG INDUSTRY is committed to overcoming shortcomings and providing integrated solutions,Taller and thickened Plates with upgraded Linear Rails increased rigidity of the linear rails to make the machine more stable,at same time reduce the flex of X And Z axis,this allow the machine to support more heavier parts and bigger size.

On the other hand,the QueenBee ULTRA make a smooth and precise surface when milling soft metals such as aluminum or other materials via it’s stability,greatly reduce the hedging during V Wheel Working.This provides more possibilities for increasing speed and high feed.

So there may a necessary to upgrade your machine.

There are many upgrade system can be used on CNC machines, such as Rod Linear Motion,Gear System,Linear Rail Guide system and other system.But after many testing and comparing,Linear Rail Guides are considered to be the most comprehensive system with its own structural characteristics.

Linear guides are generally used in linear reciprocating motion applications, and have higher load characteristics than linear bearings, bear a certain torque coefficient, and can achieve high-precision linear motion under high load conditions.

It is a kind of rolling guide, in which the steel ball rolls infinitely between the slider and the guide rail, so that the load platform can easily move along the guide rail with high precision and linear motion, and the friction coefficient is reduced to 50% of the usual traditional sliding guide, can easily achieve high positioning accuracy. The design of the terminal unit between the slider and the guide rail makes the linear guide rail bear the load in all directions, such as up, down, left, and right at the same time. The patented recirculation system and simplified structural design make the linear guide more smooth and low-noise movement.

Advantage:

-

Low noise during high-speed operation

-

New guide rail wear resistance

-

High precision and easy to disassemble

-

Simple assembly and universal accessories

-

Low cost and good efficiency

-

Its excellent characteristics have been widely used on industry, medical, science, defence, mining, construction, transportation.

The WorkBee,Lead CNC,QueenBee CNC and other machines all use T8 Lead Screws,it has low transmission efficiency,easy to wear,Long-term use will reduce the accuracy and affect the quality of the processed parts,so Community members have been pursuing a high-precision ball screw machine.So Here is it.

The ball screw drive system is a rolling screw drive system using balls as the rolling medium. According to the transmission form, it is divided into two types: converting rotary motion into linear motion; converting linear motion into rotary motion. The ball screw has the following advantages:

1. Smooth movement

The ball screw drive system is a point contact rolling motion, with low frictional resistance, high sensitivity, no chattering when starting, and no crawling at low speeds, so it can precisely control the microfeed.

2. High transmission efficiency

The transmission efficiency of the ball screw drive system is as high as 90%~98%, which is 2~4 times that of the traditional sliding screw system. For example, it can get a larger thrust with a smaller torque, and it can also be converted from linear motion to rotation. Movement (movement is reversible).

3. High precision

The ball screw drive system has a small temperature rise during movement, and can be pre-tightened to eliminate axial clearance and pre-stretch the screw to compensate for thermal elongation, so higher positioning accuracy and repeat positioning accuracy can be obtained.

4. Good synchronization

Due to the smooth movement, sensitive response, no blockage, and no slippage, the same ball screw drive system is used to simultaneously drive the same components or devices, and a good synchronization effect can be obtained.

5. High durability

The rolling contact parts of the steel balls are all hardened (HRC58~63) and precision ground. The cycle system process is purely rolling.

6. High reliability

Compared with other transmission machinery and hydraulic transmission, the failure rate of the ball screw transmission system is very low, and the maintenance of the ball screw is relatively simple. Only general lubrication and dust prevention are required. In special occasions, it can work without lubrication.

7. No backlash and high rigidity

The ball screw drive system adopts the Gothic arch groove shape to make the steel ball and groove reach the best contact for easy operation. If the proper pre-tightening force is added to eliminate the axial gap, the ball can have better rigidity, reduce the elastic deformation between the ball screw and the screw, and achieve higher precision.

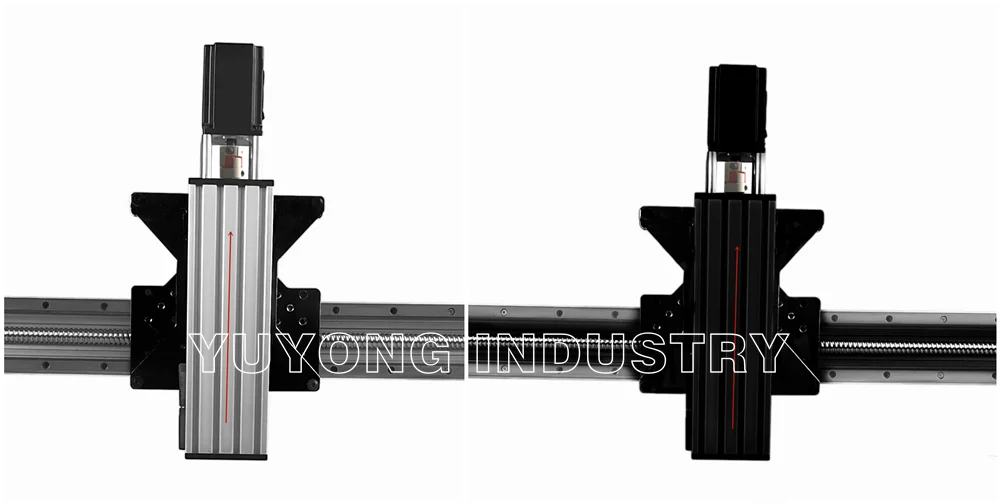

16mm Big Diamater Precise Ball ScrewIf you have experienced whipping and wobbling issues with 8mm or thin diamater lead screws on workbee and other machines, you will know how important a large diameter ball screw can be for machines with long travel. Thin Ball screw can result in reduced straightness and insufficient concentricity, resulting in distorted motion, which in turn results in a loss of accuracy. The large diameter of 16mm not only avoids whipping and shaking, but also solves the problem of sagging caused by the slender screw,Further improve the running accuracy, working accuracy, repeatability and positioning accuracy of the machine!Especially for long travel machines such as 1500mm and longer. |

|

According to YUYONG Tech Dept‘s testing,the motor type is nothing to do Ball screw Diamater! If the torque is enough, it will support any big diamater Ball Screw! The Ball Screw Diamater is nothing to do with Accuracy! According to Principles of Physics: T=(PF*I)/2π T:Drive Torque N.m P: Ball Screw Lead m I:Ball screw drive efficiency,generally 90-94% Hypothetical conditions:Horizontal load 100kg, 1610 Ball Screw,friction coefficient μ=0.1,then the drive torque T=0.01x100x0.9/6.28=1.43NM. Generally take 1.5 times the driving torque,then it’s 2.2N.M, no matter stepper motors 2.45N.m or Close Loop Motors 3.6N.m, all can meet the needs. That means With sufficient torque,the ball screw diamater never affect Torque,There is no such thing as a so called which diamater ball screw is best for Nema23 motors! 16mm is the most commonly used ball screw machine, even the smallest machines such as 3040, 6090 are using 16mm instead of 12mm! So for long Travel Machine such as 1500mm or longer,16mm is best option! Below 16mm is just for DIY machines,This is one of the reasons why the queenant can be used as a quasi-industrial machine! |

|

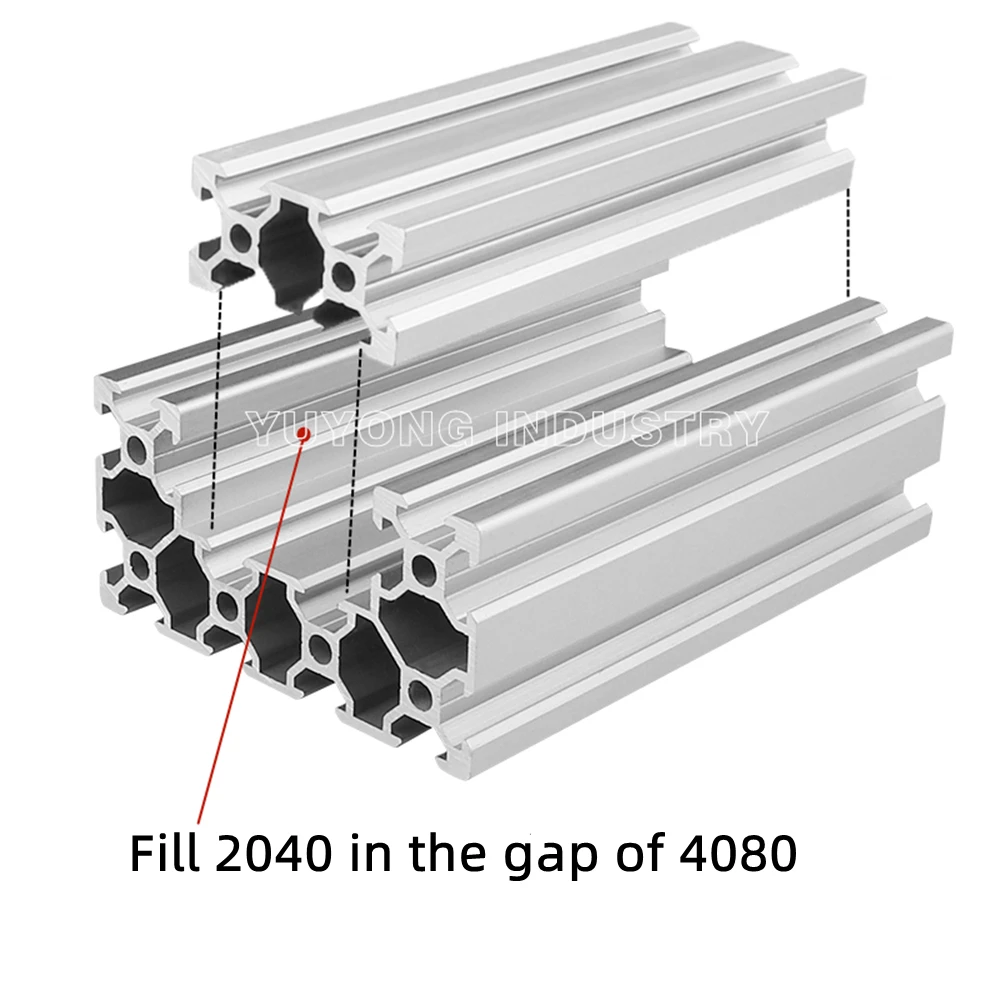

Customers have been suffering from Flexing of the X-axis for a long time when working with 2.2KW or heavier spindles.And this is obvious when the spindle is working on harder materials and longer X-axis of machines.The torsional force of the spindle causes the X-axis to twist and cause displacement of the workpiece, resulting in a loss of accuracy. The V1 has been avoids flexing as much as possible by filling 2040V-slot into 4080 C Beam Rails and add support on Back. The YUYONG INDUSTRY team redesigned the entire X-axis, added a strong 4080 C-Beam on the back, and flipped the original X-axis 4080. Through the extrusion of two 4080, a 4040 gap was formed inside, which was filled with 4040. This results in a super-strength 8080 X-axis.Twist resistance has been improved by more than 4 times after many test and compares! |

|

In previous CNC machines, the whole Z axis with spindle attach to X plate,this causes the X-axis to only be stressed on one side, and when a 2.2KW or heavier spindle is attached, it may cause vibrations when the spindle is working, which will also cause loss of accuracy and flexing of the X-axis. By attaching extra linear rail to back, and use a thick plate connect front and back plate,It not only balances the force on one side, but also greatly improves the verticality of the X axis. When the Z axis is attached, it also avoids the vibration of the spindle during operation and the shaking after a long time. |

|

All Axis use Big Diamater Ultra High Precise G7 Grade 16mm Grinding Ball Screw,One upgrade in place for your machine,It is not recommended to use a smaller diameter Ball Screw, otherwise you may need to upgrade your machine twice or more and pay more cost.The large diameter ball screw allows your machine to support a maximum length of 4 meters!

|

|

On Each Axis,we adopt Dual Linear Rails and 4 Linear Blocks to Keep the Gantry Plate balanced and upright.This greatly avoids the vibration of the ball screw and the displacement of the gantry plate caused by unbalance during work. At the same time bears the weight from the X-axis more evenly, so that the X-axis and the Y&A-axis are connected more solid and seamless!

Please don’t be deceived by some company’s advertisement, No matter QueenBee or other machines, they all use 2 linear rails+4 Blocks. Our QueenAnt machine each axis all use 2 rails+4 Blocks, Especially the Y and A aixs, they load entire X axis and Z axis, much higher loads than the X-axis,but the X axis has been used 2 rails+4 Blocks, Y and Axis should use 2 rails+4 Blocks more! Please always believe that the double rails have better load capacity, balance, stability and anti-vibration than the single rail. |

|

All bearing holes use precise Imported Metal SKF bearings for high-speed operation,with Pre-assembled bearing and plate integration,This maximizes rotation accuracy,Can bear radial and axial loads at the same time,The dynamic and static load capacity is greatly improved,Less friction torque and noise.

These advantages make it far superior to the traditional fixed on the plate a common bearing seat!

|

|

The luxurious Flat aluminum plate set up to 12mm thickness enhances the stability, rigidity and mechanical performance of the whole machine again!

|

|

|

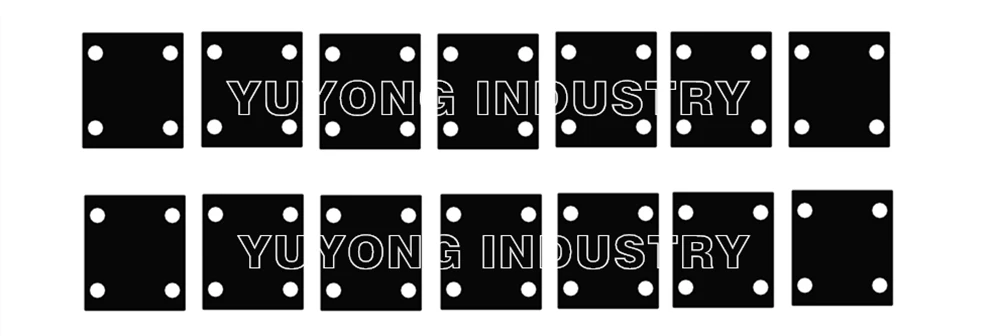

High Quality Heavy Metal Spacers Blocks attached to 4 Linear Blocks on each Axis,This ensures the vertical and balance of the aluminum plate.Leave space for the ball screw, 0 anti-backlash deviation ensures the accuracy of the ball screw!

|

|

Use Longer 340mm Z Axis Length to replace original 250mm,also use stronger HGR15 Linear Rail and Blocks to replace original smaller MGN15 Rails and Blocks.Greatly increases strength and stability!

|

|

In the gap of C-Beam Rails on Y&A axis,all filled 2040V-slot to make C-Beam a real 4080,Avoid any twisting on Y and A axis. |

|

With the new in-line bottom design allows all Y and A axes to be supported, which avoids twisting in the Y&A direction, and the movement is more linear and smoother! |

|

Payment

We accept Alipay, West Union, TT. All major credit cards are accepted through secure payment processor ESCROW.

Payment must be made within 3 days of order.

If you can’t checkout immediately after auction close, please wait for a few minutes and retry .

Shipment

Please write MUST MATCH Shipping order addresses.

Item will be shipped within 1-3 business days in normal time.

If you have not received your shipment within 30 days from payment(Brazil 60-100days), please contact us. We will track the shipment and get back to you as soon as possible with a reply.

Customs Tax

Import duties, taxes and charge are not included in the product price or shipping charge. Those charges are buyer’s responsibility.

![[Ship from EU Warehouse] QUEENBEE ULTRA CNC Full kit Linear Rail upgraded precise CNC router Engraving machine with Brand New Tensioning system](https://yuyongindustry.com/wp-content/uploads/2021/12/1515-QUEENBEE-ULTRA-CNC-Full-kit-Linear-Rail-upgraded-precise-CNC-router-Engraving-machine-with-Brand-1.jpg_Q90-1.jpg_.webp-1-300x300.jpg)

Reviews

There are no reviews yet.